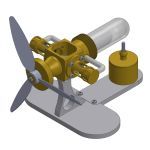

PROP H Propeller Ringbom Engine

Ringbom Engine with Airspring Floating Displacer

The Kontax PROP Propeller high temperature Ringbom engine features a twin cylinder pairing driven by an airspring floating displacer, and has a natural aluminium and brass construction. The opposed twin cylinders are self-balancing, allowing the engine to run at over 800rpm on a tiny candle-sized flame. This Ringbom inspired Stirling engine has a novel displacer arrangement with the displacer sliding on a fixed stem rather than being rigidly connected to a sliding stem.

How does it work?

This Ringbom Stirling engine works by cyclically heating and cooling the air inside the main glass chamber. As the air heats up it expands, and as it cools down it contracts. This expansion and contraction drives the twin power pistons via the connecting tubes which in turn drives the propeller. The clever thing about Stirling engines in general is that the mechanism for cycling the heating and cooling of the air is built into the engine in the form of the displacer, which in this Ringbom Stirling engine is driven by the changing pressures exerted on the main chamber by the moving power pistons.

Stirling engines are named after the inventor, Rev. Robert Stirling, who patented his idea in 1816.

The Ringbom variant is named after Ossian Ringbom, who patented his device in 1905.

Main features:

- Opposed twin cylinders

- Ringbom configuration

- Airspring displacer

- 800rpm

- Runs on a tiny methylated spirits or denatured alcohol flame

- Extremely low friction self-lubricating graphite pistons

- Built-in cylinder balancing

Materials

- Stainless steel connecting rods

- Stainless steel ball-race bearings

- Micron precision borosilicate glass cylinders

- Micron precision graphite power pistons

- Aluminium base and foot

- Brass manifold and cylinders

Dimensions

- Base - 89mm x 89mm x 4mm thick (3.4" x 3.4" x 0.16")

- Propeller - 102mm diameter x 6mm thick (4" x 0.23")

- Power piston - 6mm diameter (0.236")

- Overall height - 64mm (2.5")

- Burner - 22mm diameter x 30mm high (0.86" x 1.2")

Assembled

The engine is available fully assembled and ready to go, or in self-assembly kit form.

Instructions

Click the image below for PDF assembly, operation and maintenance instructions.

|

| Prop H Engine |

Note: Propeller colour and material may vary depending on availability.