KS90R Ross-yoke Solar Acrylic Stirling Engine

The Ross Yoke mechanism

The Kontax KS90R solar acrylic Low Temperature Stirling Engine features a unique and fascinating Ross linkage mechanism, which drives both the piston and displacer disc from the same end of the central axle with a cam-driven triangular yoke. The yoke pivots on two precision ball-race bearings, and the oval aperture at the bottom of the yoke pivots on one precision ball-race bearing. The engine also has transparent acrylic plates and is optimised for solar operation. Place it on a cool surface in the sun, such as a south-facing windowsill, and the sunlight hitting the top plate will power the engine. Alternatively you can position a small halogen or incandescent lamp near the top plate and the heat from the lamp will drive the engine.

Eco-friendly

This KS90R acrylic solar engine is the ultimate eco-friendly device, showing with one spin of the flywheel a clean and simple way of converting waste heat into motion. Because Stirling engines rely on a temperature difference for operation, they will run on almost any heat source. Although this particular solar engine is optimised for solar operation it will also run just as well from any other heat source applied to either the top or bottom plate. As long as one plate is 5°c to 10°c warmer than the other the engine will run. It doesn't matter which plate is warm, as long as the other is cooler. If you warm the top plate as in solar operation the engine will run anti-clockwise. If you warm the bottom plate by placing the engine on a cup of hot coffee or tea, TV digibox or the human hand the engine will run clockwise.

How does it work?

Stirling engines work by cyclically heating and cooling the air inside the main chamber. As the air heats up it expands, and as it cools down it contracts. This expansion and contraction drives a small piston which in turn drives the flywheel. The clever thing about Stirling engines is that the mechanism for cycling the heating and cooling of the air is built into the engine in the form of the displacer, which is driven by the flywheel and crank arrangement and moves the air from the warm side to the cool side and back again over and over.

The Stirling engine is named after its inventor, Rev. Robert Stirling, who patented his idea in 1816.

Heat Sources

- The engine can run on strong direct sunlight. The top surface will be the hot side and the bottom the cool side and the engine will run anti-clockwise.

- The engine can run on hand heat. If you have a warm hand in a cool room the engine will run from the heat of your hand.

- Placing the engine on top of a freshly made cup tea or coffee (NOT BOILING) will provide enough energy for it to run at a relatively high speed for up to 30 minutes.

- Placing the engine over a bowl of ice will provide enough temperature difference for operation. Similar to solar operation the top surface will be the hot side and the bottom the cool side, and the engine will run anti-clockwise. You can also place a dish of ice on the top plate for clockwise operation.

Main features:

- Ross linkage mechanism (named after its inventor, Andy Ross)

- Optimised for solar power, runs on direct sunlight

- Will run on a 5°c to 10°c temperature difference

- Extremely low friction self-lubricating graphite piston

- Built in flywheel balancing

- Main chamber pillars thermally isolated with nylon screws

- Regenerating power piston

Materials

- Stainless steel connecting rods and ball-race bearings

- PEEK connecting rod bushes

- Micron precision borosilicate glass cylinder

- Micron precision graphite power piston

- Aluminium main pillar, hub and spokes

- Brass chamber pillars and flywheel rim

- Brass gland and cylinder holder

- Acrylic plates

Dimensions

- Plates - 92mm diameter, 3mm thick (3.62" x 0.19")

- Displacer - 70mm diameter, 7mm thick (2.75" x 0.27")

- Flywheel - 82.5mm diameter, 4mm thick (3.25" x 0.16")

- Power piston - 9.5mm diameter (0.375")

- Overall height - 130mm (5.11")

Assembled or Kit

The engine is available fully assembled and ready to go or as a self-assembly kit.

Instructions

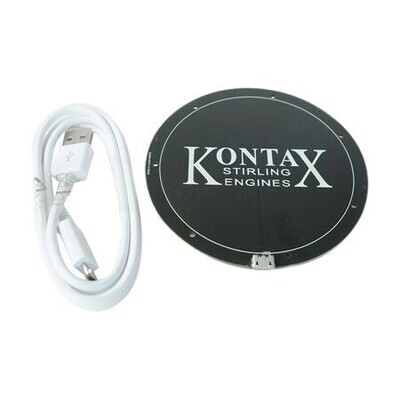

Click the image below for PDF assembly, operation and maintenance instructions.

|

| KS90R |