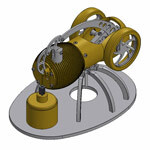

Flame Bug

Introducing our first vacuum engine - the Flame bug! This engine has a bug-like design with 6 legs, brass finned abdomen and dovetailed slide valve mouth. Bigger than our nano range of engines, this engine weighs 1kg (2.2lb).

How does it work?

This engine works differently to all other hot air engines. This is a vacuum engine (often known as a flame licker or flame gulper) which is powered by the contraction of the hot gases being cooled.

Close to external flame there is an opening into the engine cylinder which can be opened and closed with a sliding valve. When you flick the flywheel the valve opens and the piston inside the engine draws in the flame into the engine. Then the valve then closes and the mass of the brass finned body cool the hot gases inside. As the gases cool it contracts, causing a vacuum which pulls on the piston and drives the engine. Once the piston gets closer to the valve, the valve opens and the piston continues moving forward due to the inertial energy in the flywheel. This pushes the cooled gas out ready to draw in more hot air/gases in the next revolution.

Noise

The noise from this type of engine is fairly unique. You can hear the sucking of the flame into the engine and there is then a distinctive pop noise. This happens as the valve is opened and cooled gas which is slightly pressurised at this point is pushed out.

A more stable running vacuum engine

This engine has been 5 years in the making! A version was running 5 years ago but it was not quite up to the Kontax quality. Vacuum engines have a reputation for being temperamental as the flame position, size, shape are airflow are critical. The early prototype was no different. A few valve designs later and some interesting innovations has made this probably the most reliable, easy to start and stable vacuum engine you can buy. The valve and it's timing is critical, it needs to be low friction and give a good seal. The body needs to be able to absorb the heat effectively and quickly. The burner/flame position needs to have some adjustment to get optional running. And finally 4 of our 'forever wicks' are used to give a large and more consistent flame size and shape. Cotton wick will have a different size flame depending on how much is protruding and how much the cotton is frayed. The forever wicks are the same size and shape every time.

Dovetailed valve

The sliding valve is low friction and can withstand the hot temperature of the flame. It also provides just enough of an airtight seal for efficient running. A few different valve designs were prototyped but the dovetailed design gave superior performance.

Adjustable burner

Although the engine starts easily the distance between the flame and the engine is fairly sensitive. The base for the flame bug contains a magnet and the bottom of the burner has a magnetic insert. Once you place the burner on the magnet it holds it firmly in place but it also allows quick and easy adjustments. Want to move a little closer? no problem, just push it into place and it will simply stay there. Quick, easy and effective!

Main features:

- Bug like design

- Vacuum engine / Flame flicker / Flame gulper

- Runs on a methylated spirits or denatured alcohol flame

- Extremely low friction self-lubricating graphite piston

- Forever wick included (never burners down)

- Easy to adjust burner

Materials

- Aluminium connecting rods

- Stainless steel ball-race bearings

- Micron precision borosilicate glass cylinders

- Micron precision graphite power pistons

- Aluminium base, legs, and brackets

- Aluminium flywheel spokes

- Brass flywheel rim

- Brass body

Dimensions

- Base - 155 mm x 110 mm x 4mm thick (6.1in x 4.33in x 0.18in)

- Flywheels - 49 mm diameter x 10mm thick (1.93in x 0.4in)

- Power piston - 18 mm diameter (0.71 in)

- Overall height - 115mm~ (4.53 in)

- Burner - 34mm diameter x 34mm high (1.4in x 1.4in)

- Weight 1kg~ (2.2lb~)

Assembled

The engine is available fully assembled. You just need insert the wick into the burner.

Please note: EVERY flame bug is run and tested. Very slight signs of use maybe visible around the slide valve.

Instructions

Click the image below for PDF assembly, operation and maintenance instructions for this engine.

|

| Flame Bug |